Fine Tune Timing Belt

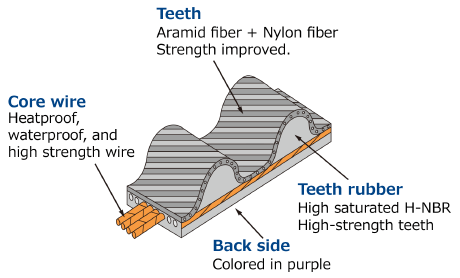

- Belt strength has been optimized for each engine application and designed to allow stable belt tension even when heat expansion occurs in the engine

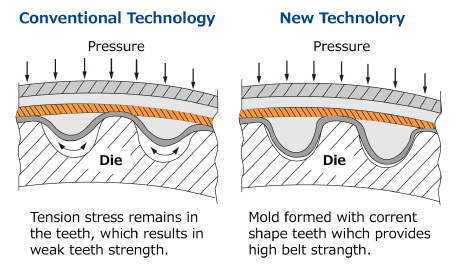

- Previous timing belt manufacturing techniques have involved with applying pressure from the outside to the teeth. This applies tension to teeth making them weaker. By forming a mould with the correct shape of teeth to begin with, it allows the teeth shape to be formed without compromising belt strength and can decrease the belt skipping at high torque engine.

- Teeth rubber is made from H-NBR grade rubber for additional strength.

- Balancer belt for 4G63 is also available. By combining both timing belt and balancer belt, the load and stress can be reduced for both engine and chassis

* Material and/or molding method may be sightly different depending on application.

HKS

In October 1973, two talented and spirited young engineers had a vision; to design and build high performance engines and components that major OE manufacturers could not or would not produce.Led by Hiroyuki Hasegawa, a former engineer for Yamaha Motor Company, and his partner Goichi Kitagawa, the two secured a capital infusion from Sigma Automotive Co., Ltd. (hence the name “HKS ”), and began tuning gasoline powered engines in a dairy-farming shed at the foot of Mount Fuji in Japan. A year later, Mr. Hasegawa designed and built the first aftermarket turbocharger for passenger cars and has never looked back.

HKS pioneered the Japanese aftermarket performance industry by delivering a host of exciting new products, including the first commercially available electronic turbo timer and boost controller. Other early products included piggy-back fuel computers and sophisticated fuel management tools. Clearly HKS was Driving Performance trends for Japanese vehicles.